By Nina Rossi

TURNERS FALLS – Metal sculptor Jon Bander of Turners Falls found that installing his found-object creations at Three Sisters Sanctuary in Goshen, MA led to close collaboration with Bruce Rosenbaum. Rosenbaum is a celebrated steampunk designer who works with a host of different fabricators on commissioned installations that go to clients worldwide through his Palmer-based company, ModVic.

(Steampunk, for those who haven’t heard the term, is a style that combines anachronistic technology inspired by science fiction with Victorian elegance, using lots of embellished industrial materials.)

Jon, who is also my son, creates sculptures from recycled gears, chains, pipes, tools, engine parts, and other industrial flotsam. His cutlery bird sculpture at Three Sisters caught Rosenbaum’s eye and the two have now collaborated fruitfully on several projects. These include a Jules Verne-inspired aquarium for a client based in Rome, Italy, which is now on display in a museum in California; a large dragon flying on the ceiling of one of the theme rooms at the Adventure Suites Hotel in North Conway, New Hampshire; and a Da Vinci-meets-Ada Lovelace-inspired “Ornijethopter” flying machine, poised on a ramp outside Rosenbaum’s “steampunk wonderland” in Palmer.

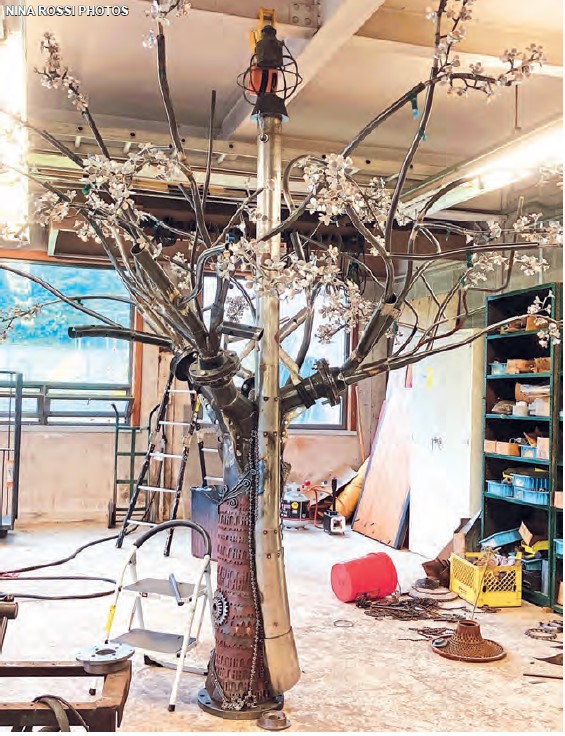

Photo by Nina Rossi: With most branches in place but with more to go, the tree starts to look more like its final form. The sheet metal stovepipe will hold a lantern at the top, and 27 bottle lights will hang from the branches.

This wonderland home and gallery of Rosenbaum’s is a 19th-century church in Palmer’s Thorndike section. Within the chapel are installations and sculptures by Rosenbaum and his wife Melanie representing the union of science, art, and history. (Visit his collection online at Modvic.com.)

Jon and Rosenbaum have hit it off, bonding over their favorite seltzer flavor (grapefruit) and their mutual love of creative reuse and steampunk. For Jon to have steady work became very important during the COVID shutdown, when galleries were closed and craft shows canceled. I have peripherally helped out on a few projects, such as installing grommets on the dragon’s wings and on the mesh panels in the wings of the Ornijethopter.

Every time I talked with Jon over the past two years, he mentioned how Rosenbaum was proposing another fantabulous project somewhere. Being dubbed the “steampunk guru” by the Wall Street Journal and “steampunk evangelist” by Wired magazine has boosted his reputation, and he’s a personable, knowledgeable, easy-going guy who is having fun doing what he loves.

Rosenbaum proposed a 15-foot-tall cherry tree for the courtyard of a condo complex in Alexandria, Virginia earlier this year and signed a contract for it in August. A large studio work space was secured in the garage at a former school in Palmer and a delivery date of late October was set.

Rosenbaum brainstorms with each client to come up with a design based on historical motifs, with a sci-fi twist, for their specific site. The narrative for the cherry tree is based on the fact that the land was once a forest owned by George Washington. Washington was unhappy that people stole lumber from his forest, so Rosenbaum imagined metal “tree guardians” around the perimeter.

Photo by Nina Rossi

The tree design incorporates axe heads and saw blades in reference to the “I cannot tell a lie” story about chopping down the cherry tree. There was once a glass bottle factory where the condos are being built, so bottle lights will hang from the tree’s branches, too.

Jon and I talked about how hard it might be to find an assistant with the right skills, creativity, and schedule to come on board at short notice for this large project. It dawned on us that I could be that person! I had machine shop and metal fabrication experience from my years at Eddie’s Wheels for Pets, and could help him ready the workspace and cut, bend, and form branches and other elements of the tree. Perhaps I would even get to do some welding!

I felt that learning from my son would help me appreciate who he has become as an adult artist. I’m an adult learner in many areas, including working for this paper as an editor. I was certain that our mutual respectful relationship would serve us well in my apprenticeship, and that I might have perspective to offer from my experience working in diverse mediums.

I took a month-long break from this paper in September to work on the tree. At first, I really was exhausted by it. The studio is in the maintenance garage of the former school, and a variety of materials needed to be sorted and moved to make room for the project, including bundles of roofing shingles, a pallet of brand new heavy-duty cots, and other miscellaneous items.

There were bins and bins of nuts and bolts, gears, and other machine parts from a factory cleanout Rosenbaum helped with that needed to be organized into shelves and drawers. We struggled to locate proper outlets to plug in welding and other equipment, and tried to organize and tally our stock of steel pipe.

Working with Steel

My arms were weak from working with words, no longer used to slinging around metal things and handling equipment. It was an unfamiliar feeling to be “job-soft,” but hey, after all, I am now a 61-year-old woman. The grinders and saws felt big, heavy, and unwieldy. It took a while to get used to them.

The first tasks were the hardest. The pieces of pipe we were cutting for the trunk were eight or ten inches in diameter, with flanges to fit. Cutting and grinding the steel to prep pieces for welding created a fine black grit that got everywhere.

Photo by Nina Rossi

I felt tired, and old. I was sad that I didn’t have the skills to help with the structural welding, as there was a lot of it to do to attach the flanges, trunk, and base together, but glad to be back working with metal, a most solid and purposeful material. Gradually my arms and hands got used to holding the grinders and cutters. I marveled at the convenience of the little Milwaukee cordless bandsaw and its corded big brother, which I used to cut rods and pipes and make convex “fish mouth” joints on them.

Eventually I got to weld, too. I got used to the short fizz of sparks on bare skin, and to finding tiny scabs on my arms and holes in my shirt after a day of it. I had hoped I would be able to get the hang of welding almost instantaneously, being a mom to two welders already, an artist in many mediums, and all that – but it has been a very humbling experience, haha!

It is not like sewing a seam, as I had hoped. It’s been hard to get used to the darkness of it – the helmet visor going black, the work only lit up by the light of the weld, the spark and molten metal as the nozzle moves along. I learned that part of it is hearing, learning how to make the right bzzz of the welder that indicates things are going correctly.

Many times I felt the wire of the MIG welder shoot out of the nozzle, missing the piece entirely, because I was off target. Or heard snarling pops and crackles from being too far away from the work or moving too quickly over it, resulting in bubbles and splatters. I would have to stop and cut off the excess wire, or grind off unsightly blobs and bubbles of metal.

Jon would come over, look at my welds, and shake his head. “Mom – try sitting down so you can brace your hand. Welding is all about getting in a comfortable position,” he advised.

Oh, OK. I’ll try that – thanks!

As the tree has grown, the diameters have gotten smaller, starting from the base of a 10” pipe trunk. In addition to preparing those big pieces for Jon to weld, I bent smaller and smaller branches, starting at four inches, to three, to two, and then one and now half an inch, with the quarter-inch rod twigs and ¼-20 bolt blossom stems. We started by cutting angles on the four- and three-inch pipes, then turning and welding them, then bending the smaller ones in a hydraulic pipe bender.

Jon heated and hammered transitions between large and small pipes to smooth them out. The little twigs have been bent with a small jig clamped in a vise. For the last two weeks I have been welding quarter-inch twigs onto half-inch steel pipe and rod branches.

Photo by Nina Rossi

We have made the 27 branches that will carry the bottle lights, and now the rest of the branches can be solid. There may be a hundred or more to go.

Bloomin’ Aluminum

I have also been the blossom maker for the cherry tree. Since over a thousand blossoms would be needed, we pondered how to accomplish such mass production. Nibbling individual flowers or petals out of sheet metal with a shear by hand would be impossibly slow. I thought of weathervane and ornament maker Marian Ives of Hawley, Mass., who uses an old stamp press to cut out her metal ornaments, and called her to find out if we could use it to make our blossoms.

Yes, it turns out, Marian would lend us the use of her press, and if we gave her a drawing, she could cut our custom blossom stamp out of tool steel. We would just need to order an appropriate amount of aluminum sheeting of the right thickness for the press.

We bought .28 gauge aluminum rolls from a roofing company in Alabama, and I went to Ives’ Shelburne studio to turn 60 linear feet of 14” wide metal into almost 1,500 five-petaled cherry blossoms. The press was operated by kicking a pedal with one foot, causing a heavy weight to slam the two sides of the stamp together and cut the 2½” flowers out of 3” wide strips of aluminum. After each one was stamped, it had to be trimmed, and then I punched a quarter-inch hole in the middle for a bolt to pass through. Each blossom is then cupped and shaped by hammering it into a hole, and then the petals are hammered open slightly, creating sparkly facets of shiny aluminum.

The bolts are welded to the twigs. One nut is threaded on, then a blossom is laid on it with a second nut to hold it tight. A tack weld on top of each assures that they are there for good.

Trunk and Roots

While I have been busy with the blossoms and twigs, Jon has been fashioning and decorating the tree’s roots and trunk. A sheet metal channel, housing the electrical box for the lights at the base, runs up one side to terminate in a lantern at the top. Antique saw blades swirl and wrap around the trunk. Here and there, a quarter peeks out of a steel spiral, and Washington’s signature wraps around one side under the flange.

Photo by Nina Rossi

A line of hatchet and axe heads marches up next to spirals of steel rod and chain. Weld beads create texture to decorate some areas, and 13 stars will be applied to signify the original American colonies. Gears welded to the trunk enhance the industrial look, as well as the large pipe flanges bolting together the top and bottom sections and defining branch quadrants.

The deadline has now been extended to mid-November, and while I have started back at the paper this month, I continue to help Jon on other days. I have about 450 more blossoms to finish, and dozens of branches to complete. Then, the electrician will wire the bottle lights and put quick-connects at the junctions so that the tree can be transported in sections and assembled on site.

This has been a priceless experience, a unique challenge that I am really glad to share with my son. Unlike the many reality shows that feature the drama of family business ventures, we haven’t had any disputes. We have each had “melt-downs” sparked by equipment malfunction and talked each other down from frustrated states of mind. This is not my area of expertise, so it is amazing to me how Jon’s creativity leaps forward on the technical knowledge of the different processes involved. Knowing what is possible with the tools and equipment, means he can think in a totally different direction than someone like me who isn’t experienced in that area.

Of course, I’ve thrown in a few mom things like lunchtime smoothies, leftover meals, finding lost tape measures and pencils, and the general tidying-up of stuff.

I’ll share an update after the project is installed in November. I hope to be a better welder by then!

First published in the Montague Reporter on October 28, 2021 – montaguereporter.org

Photo by Nina Rossi

Welding a Family Tree, Part II

By Nina Rossi

TURNERS FALLS – In our October 28 issue I described working with my son, Jon Bander, on a large metal sculpture of a cherry tree this fall, but I left the story of the project unfinished. Now I am happy to report about how it was finished and installed on November 19 in the courtyard of the Park & Ford condominium complex in Alexandria, Virginia.

The sculpture was a commission obtained by ModVic, a Palmer, Mass.-based steampunk design company spearheaded by Bruce Rosenbaum.

Steampunk, for those who haven’t heard the term, is a style that combines anachronistic technology inspired by science fiction with Victorian elegance, using lots of embellished industrial materials. (This description was inadvertently cut in the first article, which said steampunk is “a style that combines materials”!)

The cherry tree sculpture has a George Washington theme because its destination is on land once owned by Washington – there are axe heads and sawblades and George’s signature on the trunk. Other “easter eggs” hidden in the sculpture include a heart with “GW & MW” carved on the trunk, Washington quarters in the bark, 13 stars climbing the tree for the 13 colonies, and the dates of Washington’s term of office.

Bander and Nina Rossi tighten bolts on the base of the tree. Photo by WILLIAM HAYS

Besides fabricating the trunk, limbs, and branches out of hundreds of feet of pipe and rod, we stamped out, trimmed, and formed 1,500 aluminum blossoms and fastened them to twigs to make the tree look like it is in full bloom. Twenty-six bottle lights are attached to the branches, and a glowing red brass lantern sits at the top of a 13-foot-tall stovepipe snaking around the trunk. (This feature also incorporates a waterproof junction box for the wiring.)

Two anemometers ride on top of this red-lit lantern, set to catch wind in different directions, and vintage brass propellers are attached to the sides for more kinetic effect.

The Final Stretch

The project started the first week of September. When I left on vacation the last week of October, Jon and I had been working an assembly line of sorts to weld twigs onto branch sections and fasten each blossom between two nuts. At that point I assumed I’d be back at the shop helping for the final push in the first two weeks of November.

But while I was gone, Jon zoomed through the rest of the branches, installing them on the tree and then finishing welding the texture of bark on the trunk and branches. “I’ve used 40 pounds of MIG wire – four spools’ worth – on the bark texture, all told, “ reports Jon. “I also added up over 400 feet of quarter-inch rod used for the project.”

(Perhaps my amateur welding was actually holding him up just a bit? But he swears that is not the case!)

Another task Jon completed during the final three weeks was applying a patina. “I use a copper sulfate solution, then a hydrogen peroxide, vinegar, and salt mixture. The copper sulfate makes a darker green and red, whereas the other solution adds depth and texture and a real rich, red-orange rust look,” says Jon. “I spray it on, then wash it. With the peroxide mix, I also throw more salt on it. There are also some parts I heat up and then put linseed oil on to turn them black.”

When I asked how he knew about these patinas, his one-word answer was no surprise: “Google.”

The branch sections come off the main trunk at four flanges, and the trunk itself was flanged into two 600-pound sections. This means all the wiring clips together at those seams, and the tree can be taken apart for transport on a rented trailer.

As we fabricated the branches, Jon and I were careful to leave room for the wires to pass through to the tip by not making sharp bends in the pipe. On the solid branches, this didn’t matter, and I drew those rods through the bender willy-nilly, trying to achieve a deliberately random “natural” effect. Nevertheless, my random manipulations also shared characteristic bends, divisions, and blossom terminations that resulted in a nice, organic rhythm.

Jon decided to include a cardinal, the Virginia state bird, on the tree, and made one out of spoons and other cutlery pieces. He welded it to a branch and painted it red.

I wondered how Rosenbaum was able to find an electrician to tackle wiring this thing. “The project needed a wiring specialist and inventor who could work with the ‘organic’ forms of the tree branches and design, and build the hanging electrical sockets,” Rosenbaum explained. “Jeremy Griswold, a creative problem solver, was the perfect person to make it all come together.”

Lighting the Tree

The tree’s first assembly and lighting took place on November 13 in Palmer. With heavy rains and winds threatening that day, the crew decided not to try to assemble it outside the garage doors of the workshop at the former Converse School, but to put it together indoors.

“With the 12-foot-high ceilings in the workshop, it was not quite high enough to see all the assembled pieces together,” said Rosenbaum. “We put it all together for the first time in the school’s gymnasium with 30-foot ceilings.”

When I arrived at the school it was blustery, and night had fallen. Once inside the doors, a heavy rain began throwing sheets of water against the building. I hurried down the dark hallway towards the golden glow of the gym, anxious to see how things were going in there.

The tree was at the near end of the basketball court, with its trunk bolted together. One branch quadrant was installed, with the other three sections on pallets nearby. A cart full of boxes and electrical supplies stood ready and there were three ladders set up.

Rosenbaum, Jon, and Jeremy paced around the tree, gazing upwards. Was the ceiling leaking? I looked at the doors and realized that the two trunk sections must have been assembled inside the gym. How did they put the upper section of the trunk onto the lower part, given that it weighed about 600 pounds – did they lift it up by hand?

(from left) Electrician Jeremy Griswold, Bruce Rosenbaum of MocVic, sculptor Jon Bander, and Nina Rossi at the first assembly and lighting of the tree in Palmer. Photo by WILLIAM HAYS

It turns out that the three of them used the basketball backboard frame coming down from the ceiling to attach a chain hoist, and lifted up the top of the tree. Then they slid the bottom under it and lowered it down.

The team installed the top of the stovepipe with the lantern light, then tried to put on the next quadrant, but found they couldn’t. The electrical stuff had to be clipped together while the flanges were within inches of each other, and the holes then had to be lined up just right for the bolts to pass through.

The big, awkward, heavy-but-delicate tree section was hard to grasp and hold. The crew attached a rope around the ceiling girders, hooked the hoist to that, and wound straps around the branches. Rosenbaum worked the hoist, with Jon and Jeremy on ladders to guide the flange into position. They snapped the connections together, and threw home the top bolt as Rosenbaum lowered it gently down.

Section three went up the same way, and the fourth was light enough to do by hand. We left for dinner while Jeremy stayed to hook up the lights.

When we got back, all the bottles were hanging from a rod-and-disc device that Jeremy had machined, which fit inside the bottle necks and then attached to a hook on the tree branch. This took the strain off of each wire as it went from steel pipe to glass container. Three of the bottles were actually antiques, made by bottle companies that had once been at the condo site.

They plugged it in – hooray! It works! “It was an incredible magical moment! As if the tree came to life right before our eyes,” says Rosenbaum.

Jon recalls that he had “spent so much time around it, seeing it in pieces, without seeing it all together. I felt relief – it worked! That was great! But it’s hard to be really excited about it after spending so long building it. I wish I could see it for the very first time as other people do.”

Installation

On November 18 Rosenbaum and Jon drove down to Virginia, towing the tree sections bolted and strapped down to a 12-foot trailer. Bubble wrap protected the blossoming branches from road dirt and wind burn.

At the construction site, both the general contractor and some ironworkers were there to get the job done. They unloaded the trailer at 8 a.m. and then set up a gantry crane to lift the pieces into place in the courtyard planter. By 2 p.m. all the pieces were assembled on the tree.

Bander and the ironworkers who installed the tree on site at the Park & Ford condominiums in Alexandria, Virginia. Photo by BRUCE ROSENBAUM

“It took a few hours to get all the bottles and lights on, and then to waterproof the connections,” says Jon. “I didn’t realize the buildings were so big. Fourteen stories! It looks a lot smaller there. But there are some other trees in the courtyard about the same size, so it kind of fits right in.” He spent a few hours walking around the tree, taking pictures, even laying down underneath it.

“I was amazed and impressed that it went up without a hitch,” says Rosenbaum. “The only small repair was putting back the ‘F’ in ‘Park & Ford,’ because it fell off during transit – nothing a little JB Weld couldn’t fix. The owners saw the fully installed tree and were blown over! I’m hoping that Jon and I will have more projects with them in the near (retro) future.”

This week, Jon says he is glad it’s over. He put almost 500 hours into the project. “I’ve been thinking about that project for about a year. Working it out in my head, and then doing it step-by-step. The first month was the most intense part, doing 12-hour-plus days and driving two hours a day.”

But,” he adds, “it was really fun working with you, Mom.”

Jon Bander’s work is online at notorious-weld.com

First published in the Montague Reporter on December 2, 2021 – montaguereporter.org